Safety & Health Compliance EMI / EMF Testing Surveys for Pacemakers & Implantable Medical Devices

As an increasing number of individuals have lifesaving and life-enhancing biomedical devices surgically implanted in their body, the need for testing home and workplace safety has also become more commonplace.

Also, the electromagnetic environment that these implantable biomedical devices are exposed to has become more complex and intense with an increasing number of potential sources of interference.

ScanTech Technical Consulting has years of experience in researching, surveying and documenting environments in order to determine potential risk factors. In some cases, the real danger can come from unexpected sources, such as a large section of magnetized metal in the workplace or a high powered 2 way radio.

NEED A PACEMAKER EMI TESTING SURVEY / MEDICAL DEVICE ELECTROMAGNETIC INTERFERENCE (EMI) ENVIRONMENTAL SITE SURVEY?

214.912.4691

If your company has an employee with a biomedical implant and needs a “return to work” medical clearance from either their doctor and / or your EH&S / medico-legal department or company doctor, and / or you have concerns about the EMF exposure in your workplace, then give us a call. ScanTech has extensive experience with pacemaker EMF surveys and other potential EMF / EMI surveys for any type of biomedical implant with respect to the following types of work environments and more:

- Manufacturing facilities

- Refineries

- Power plants

- Electrical substations or other heavy electrical duty environments

- Hospitals

- Automotive Production Lines

- Foundries

- Offshore Oil Rigs & Production Platforms

Types of Biomedical Implants

Implanted pacemakers, implantable defibrillators, EEG, (electroencephalograms) electrocardiograms, neuromodulation devices, neurostimulators including SCS (Spinal Cord Stimulators), ambulatory EKG (Holter Units), ICDs, (Implantable Cardioverter-Defibrillator) Medtronic Strata CSF valve shunts, PA (Pulmonary Artery) pressure sensors, CRTs (Cardiac Re-Synchronization Therapy devices including CRT-D Defibrillator CRT-P Pacemaker), IPGs, (Implantable Pulse Generators) Vagus Nerve Stimulation / Stimulators, (VNS) Deep Brain Stimulators (DBS) and external medical instruments such as insulin infusion pumps are susceptible to a variety of EMFs, (electromagnetic fields) EMI (Electromagnetic Interference) and electrostatic discharge (ESD) events.

TYPICAL PACEMAKER SERVICE AREAS: Houston, Austin, Dallas, Texas, Michigan, Iowa as well as other states and International travel available

NEED A PACEMAKER / BIOMEDICAL EMF SURVEY QUOTE?

Please provide the following information:

1) Physical address of facility and basic layout relevant to employee duties including rough square footage involved (Scope of Work)

2) Contact information including email, best phone number(s)

3) Company name and nature of business

4) Examples of the kinds of equipment used or worked arounds that employs magnetic, RF (radio frequency) or high current

5) Timeline to accomplish

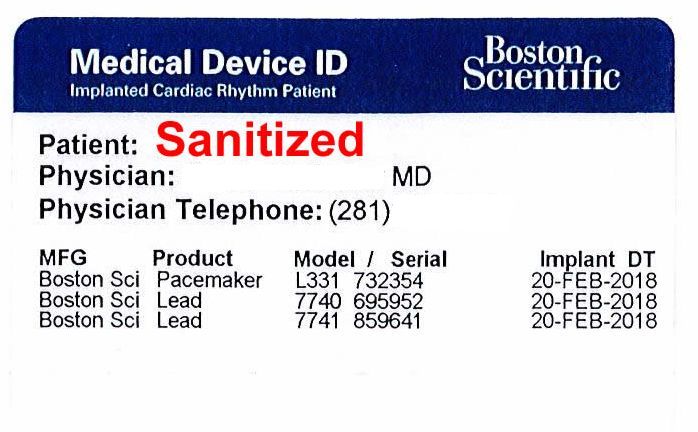

6) Type of biomedical implant including Manufacturer, Model & Serial # as shown below *

7) What are your typical payment terms and what is your vendor vetting process like (what paperwork needs to be filled out to establish a working relationship)

* For biomedical implant surveys, we need the make, model and serial number of the device with the employee’s name “sanitized” out for HIPAA compliance as shown:

Sanitized Pacemaker Biomedical Implant Device Card

ScanTech Technical Consulting has had experience in performing EMF testing and EMI surveys for the following manufacturers of implanted biomedical devices:

- Medtronic

- Boston Scientific

- Abbott Laboratories / St. Jude Medical

- Mortara

- Nevro

- Biotronik

- Tandem Diabetes Care

While newer generation designs tend to be more resistant to external influences, I still routinely find sources of EMF interference that exceed the manufacturer specifications, particularly in work and industrial environments. (but residences are not exempt for reasons discussed below)

This is due to a number of reasons:

1) Our electromagnetic spectrum is more crowded than ever and we are constantly adding new electronic devices and spectral intensity to our everyday environment. Examples include:

- Wireless phone chargers

- Battery chargers for electric vehicles & power tools

- WiFi, Wireless Internet and Bluetooth

- Hybrid Electric Vehicles (HEVs)

- Wireless microphones and media systems

- Smartphones – cell phones, cordless phones

- Security scanners for weapons detection

- RFID (Radio Frequency Identification) reader systems for entry control

- Portable music devices, Bluetooth Speakers, headphones for iPods and MP3 players

- Laptops, tablets, desktop computer power supplies

- Electric scooters, drones, hybrid & electric vehicles including scooters, utility vehicles, golf carts, Segways, Gators, etc.

- Internet access points, wireless repeaters, amplifier boosters and cellular phone boosters (AWS or Advanced Wireless Systems in the 1.7 GHz range)

2) Many industrial and manufacturing environments have equipment which emits and broadcasts EMFs at relatively high power levels over a broad range of frequencies:

- Electric welding equipment (MIG, TIG, SMAW, etc.) and welders

- Corded and cordless power tools

- Generators, alternators

- RF clam shell sealers

- Semiconductor fabrication plant assets

- UPS (Uninterruptible Power Supply) banks & DC battery backups

- Cleanrooms / semiconductor fabrication equipment

- AC and DC motors found in blower motors / fans, HVAC equipment, pumps

- Walkie-talkie base stations & 2 Way Radio Microphones

- Induction furnaces

- High powered DC Rectifier arrays

- Transformers, medium & high voltage power lines & substations

- Industrial electromagnets

- High powered industrial CO2 (Carbon Dioxide) and YAG fiber optic lasers in the kW (kiloWatt) range

- Magnetized structural beams

Electric Motor Types

3) Some facilities have entire areas that are flooded with electromagnetic energy such as:

- Electric substation yards

- MCC (Motor Control Center) rooms with 4160 V & 480 V switchgear panels and power feeds

- VFD – Variable Frequency Drives (AC) and VSD – Variable Speed Drives (AC & DC power)

- Incorrectly wired infrastructure which can set up unexpected fields in a large area

- Chemical cell rooms (found in agrochemical, alkali chemical production facilities)

- Cellular / microwave towers 3G, 4G, LTE (Long-Term Evolution) and other RF equipment on tall building rooftops

- MRI Rooms in hospital and medical facilities

and so forth can all cause malfunctions and intermittent operation in nearby mission critical electronics. Significant DC magnetization has even been found in the structural metal of buildings and in ferrous alloy stock.

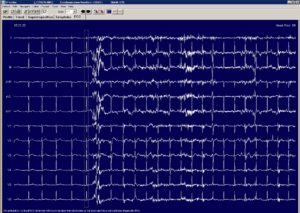

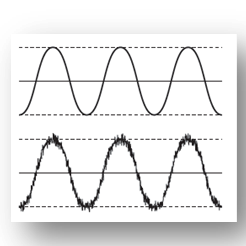

60 Hz AC EMI Electromagnetic Interference noise on an ambulatory EKG Holter Unit from an actual ScanTech project

4) There are environments which may have unexpected sources of high magnetic fields. I once did a survey of an exhibit in a museum where one of the plasma display items possessed an unusually high magnetic field that was worth investigating. Hospitals and scientific research centers may have MRI (Magnetic Resonance Imaging) and NMR (Nuclear Magnetic Resonance) equipment which uses exceptionally strong DC magnets and Radio Frequencies.

5) Even in conventional office buildings you have server rooms, electrical rooms and conventional power transformers next to employee working areas. It is also not unusual for some areas to have “rogue” transmitters for personal wireless or even corporate eavesdropping devices.

The confluence of the above effects may cause unexpected performance issues in even the most sophisticated biomedical devices and equipment through either radiated near field or conducted interference.

RF & wireless interference is a common issue in many mysterious anomaly situations. Computer controlled systems can be highly susceptible to interference from both radiated and conducted sources, and this can include server rooms, A / V equipment, security systems, hospital monitoring systems, etc.

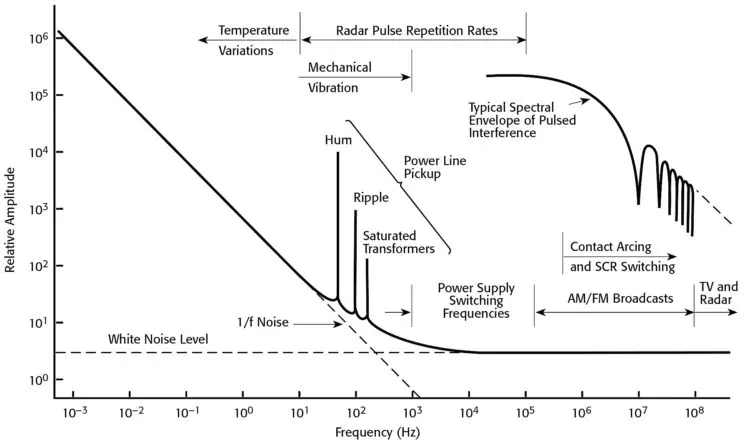

Electromagnetic Interference EMI Testing Voltage Noise Frequency Spectrum

As more technologies such as WiFi, Wireless Internet, Bluetooth, RFID and other communication linked technologies began to saturate offices and manufacturing plants, the potential for conflicts only increases. An experienced consulting company such as ScanTech can help minimize downtime and frustrating delays by quickly isolating and mitigating such interference problems.

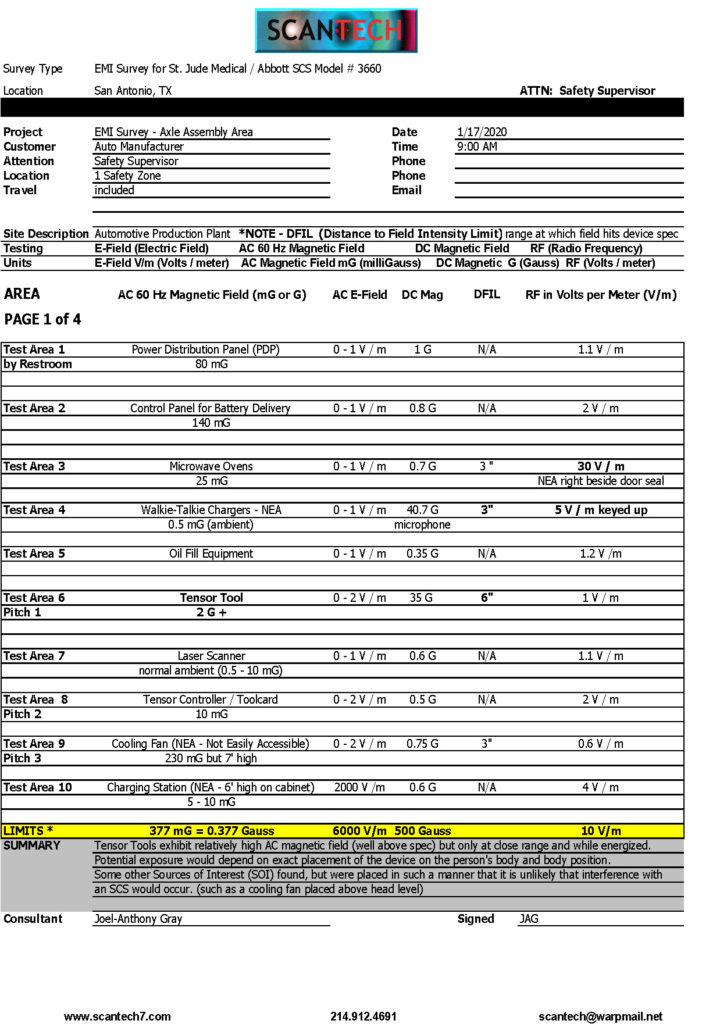

EMF EMI Survey Report Biomedical Implant Report ScanTech Example SANITIZED

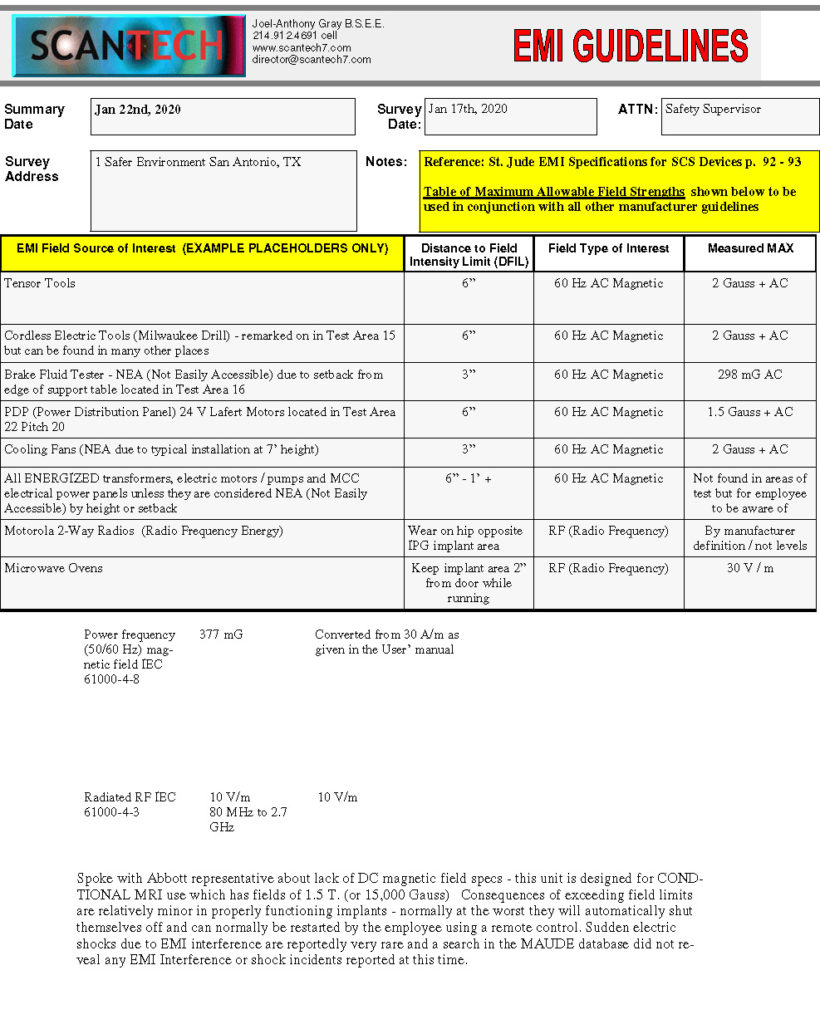

EMF EMI Survey Guidelines Pacemaker Table Sanitized Report with DFIL (Distance to Field Intensity Limits)

EMF EMI Survey Guidelines Pacemaker Table Sanitized Report

ScanTech also has experience in working with child / infant anti-abduction systems by Stanley Healthcare (HUGS) and McRoberts Security Technologies. (MyChild)

While ScanTech is based in the Dallas – Fort Worth area, we have done numerous EMF & EMI surveys for biomedical devices and bio-instrumentation in the Houston, Austin – San Antonio area and nationwide / international. (particularly Michigan and Iowa where there is a heavy industrial presence)

Biomedical imaging including X-Ray projection radiology, MRIs, (Magnetic Resonance Imaging) CT (Computed Tomography) machines, portable ultrasound and other diagnostic equipment is subject to interference from a variety of sources including the power mains, computer interface, etc. particularly since they can be operated in a variety of modes under varying environmental conditions.

ScanTech has experience in working with bio instrumentation, biomedical sensors, X-Ray equipment, portable MRIs, and taken coursework covering the fundamental physics behind nuclear medicine, radiology, ultrasound and other imaging modalities.

BIOMEDICAL IMPLANT SURVEY LINKS

FDA MAUDE (Manufacturer User Device Experience Database

Boston Scientific Technical Support Lines

IEC 61000-4-8 AC Magnetic Field Standards

Agilent IEC 61000-4-8 AC Magnetic Field Specs – PDF Format

Manuals for St. Jude Medical / Abbot Laboratories Biomedical Device Implants

Medtronic Biomedical EMI Testing – PDF Format

Boston Scientific Electromagnetic Compatibility Guide.pdf

Spinal Cord Stimulators (SCS) & MRI Questions

CardioMEMS PA HF EMI Testing Manual – PDF Format

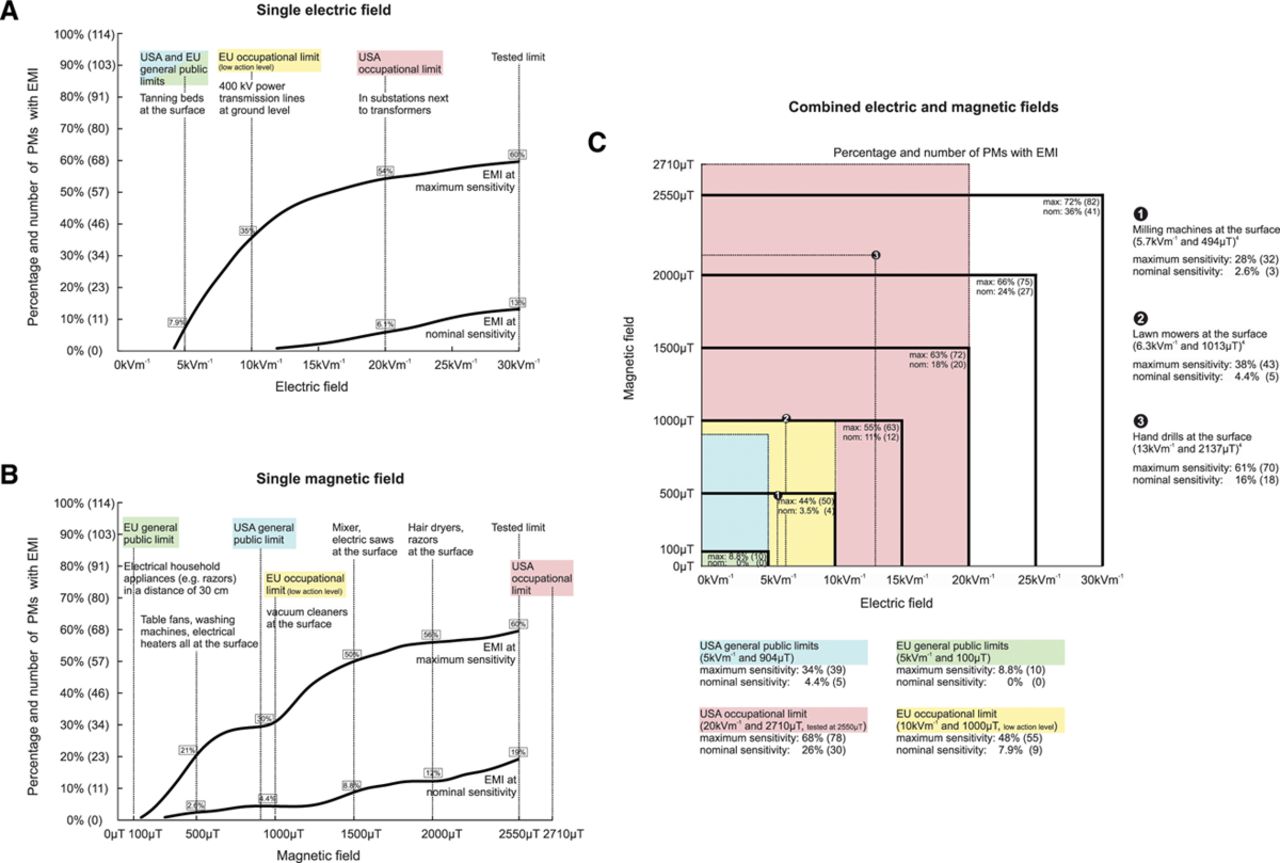

Environmental Electromagnetic EMI Interference Pacemakers ICDs – PDF Format

Implantable Biomedical Devices Pacemakers EMI Testing Electromagnetic Environment – PDF Format

Electromagnetic Interference EMI Pacemakers ICDs Technical Paper- PDF Format

ICNIRP EMF Survey Guidelines – PDF Format

EMI Pacemakers Magnetic Electric Interference – PDF Format

Pacemaker Interference EMI from Electric Magnetic Sources

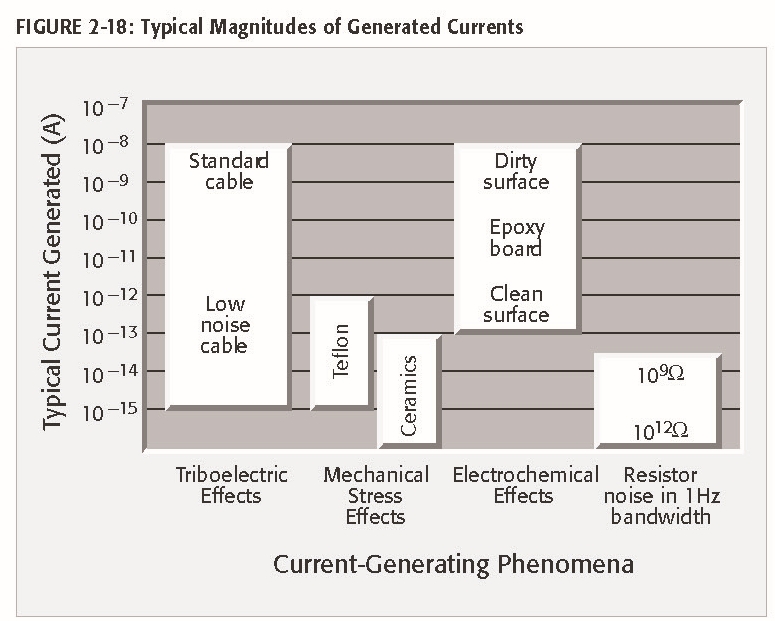

EMI Electromagnetic Interference -Typical Magnitudes of Generated Currents

Low Level Measurements Handbook 7 Ed PDF Format

MEDICAL RADIOLOGY & RADIATION LINKS

Ionizing vs. Non-Ionizing Radiation Purdue University

Ionizing vs. Non-Ionizing Radiation Archived Page

MEDICAL IMAGING SOFTWARE

Open Source Medical Imaging Software

(includes a link to 3D Slicer below)

3D Slicer Medical Imaging Software (reads DICOM medical image files)

3D Slicer DICOM Medical Image Tutorial Page

Resource for sample DICOM Medical Image Files

ESD / Electrostatic Discharge Testing and EMI (Electromagnetic Interference) in Control Equipment for Manufacturing & Biomedical Equipment in Hospitals

214.912.4691

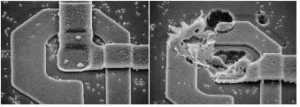

Decades ago when integrated circuits first came out in consumer products and computers, they were unusually susceptible to ESD or static discharges of electricity. These initial devices typically employed TTL or Transistor Transistor Logic, which is now considered a rather rugged technology compared to modern MOSFET (Metal Oxide Semiconductor Field Effect) transistors that have a thin gate oxide (sometimes as little as 1 nanometer) that is easily punctured by an errant voltage.

In most cases, the older TTL devices would simply latch or lock-up and a reboot was necessary along with a spray of Static Guard or some other anti-static chemical to prevent recurrence. Engineers designing these circuits got more experienced at designing them so that external discharges would not perturb the device, and for a long while, static electricity has not been a consideration except when replacing internal components on a board or in a computer.

But with the numbers and density of the MOSFET transistors on an integrated circuit not only growing exponentially, it has become more sensitive because the feature sizes of the transistors themselves have grown smaller and smaller, well past the deep sub-micron range and into the low nanometer scale, and the unwelcome specter of ESD damage has returned. Even if not caused by a static discharge, it is not uncommon to find that a number of consumer electronics plugged into the wall socket has been permanently damaged after a severe thunderstorm or other electrical outage.

It only takes about 100 – 300 V of static electricity to damage a transistor, which is well below the threshold of 3000 V that you feel from a shock when touching a grounded metal object after walking across a carpeted floor on a cool, dry day. Sparks with voltages upwards of 30,000 volts are not uncommon under certain conditions and can easily wreak havoc on mission critical equipment.

Contact ScanTech for an evaluation of your environment to detect conditions, materials and procedures that may be causing equipment malfunction, employee / patient shock incidents and possible explosion hazards in hospitals, clinics, biomedical labs, warehouses, data centers and areas with expensive and sensitive equipment as well as potential flammables. Data derived from special instrumentation such as air ion counters, charge sensors and surface resistivity meters which are designed to measure static electricity and the effectiveness of anti-static protocols such as static dissipative vs. static conductive will be used to suggest the best course(s) of action.

Comparison of a “Clean” Powerline Signal (top) with one that has EMI or High Frequency Noise (bottom)

Electromagnetic Field Interference Surveys / EMI Testing & Consulting

In addition, ScanTech has the equipment to measure and perform a variety of electromagnetic field (AC / DC / RF) EMF and EMI testing as well as the detection of harmful radioactive material.

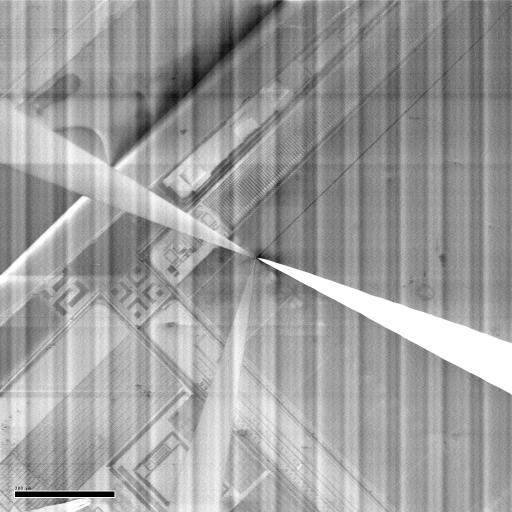

We are experienced in troubleshooting EMI / EMC (Electromagnetic Interference / Electromagnetic Compatibility) Problem Diagnosis & Resolution of Computer & Equipment Interference due to RF and grounding / ground loop issues in server rooms, near RF sealers, MRI equipment, SEM (Scanning Electron Microscopes), sensitive nanotechnolgy equipment, semiconductor manufacturing, etc.

Medical Device / Biomedical Equipment EMF / EMI Compliance Testing: We have performed numerous surveys for companies and corporations with pacemaker / implantable defibrillator / ICD interference concerns for all major manufacturers of these devices. We have also done interference testing for EEG, EKG, Holter units (ambulatory EKG) and other biomedical equipment.

60 Hz Banding Scanning Electron Microscope EMI

What if it isn’t EMI? (Electromagnetic Interference) ScanTech can still assist in troubleshooting and discovering what is really going on due to our extensive interdisciplinary background. In many cases, the client assumes the problem is due to some external field, but the real issue can often be something unexpected and even less expensive / easier to fix than thought. A fresh insight from a highly experienced interdisciplinary consultant can rapidly resolve your nightmare scenario at great cost savings.

ESD / Electrostatic Discharge Links

Emitter Point Maintenance for ESD Control Ionizers

Prostat University Webinar Series on ESD

ScanTech Technical Consulting performs Biomedical Implant Testing for Pacemakers, Heart / Cardiac Devices, ICD’s, Implantable Cardioverter Defibrillators and Ambulatory EKG Holter Units made by Medtronics, St. Jude Medical, Boston Scientific and Mortara. We also perform RFID / RF / EMI Interference testing and surveys for infant / child anti-abduction security systems such as HUGS (Stanley HealthCare) and MyChild. (McRoberts Security Technologies)

Fields Tested for :

DC Magnetic Field: 3 Axis DC Gaussmeter

AC Magnetic Field in the low ELF frequency ranges such as conventional 50 / 60 Hz powerlines

AC Electric Field in Volts / Meter V/m

RF Fields (AC fields from 1 KHz to 8 GHz)

Boston Scientific Potential Implant Behaviors from Electromagnetic Interference

MORE INFORMATION ON THE MAIN SCANTECH SITE

[smartpwpages]